EFFECTIVE

INNOVATIVE

CONTEMPORARY

PRODUCTION

TECHNOLOGIES

COMMUNICATIONS

EN

Track machinery

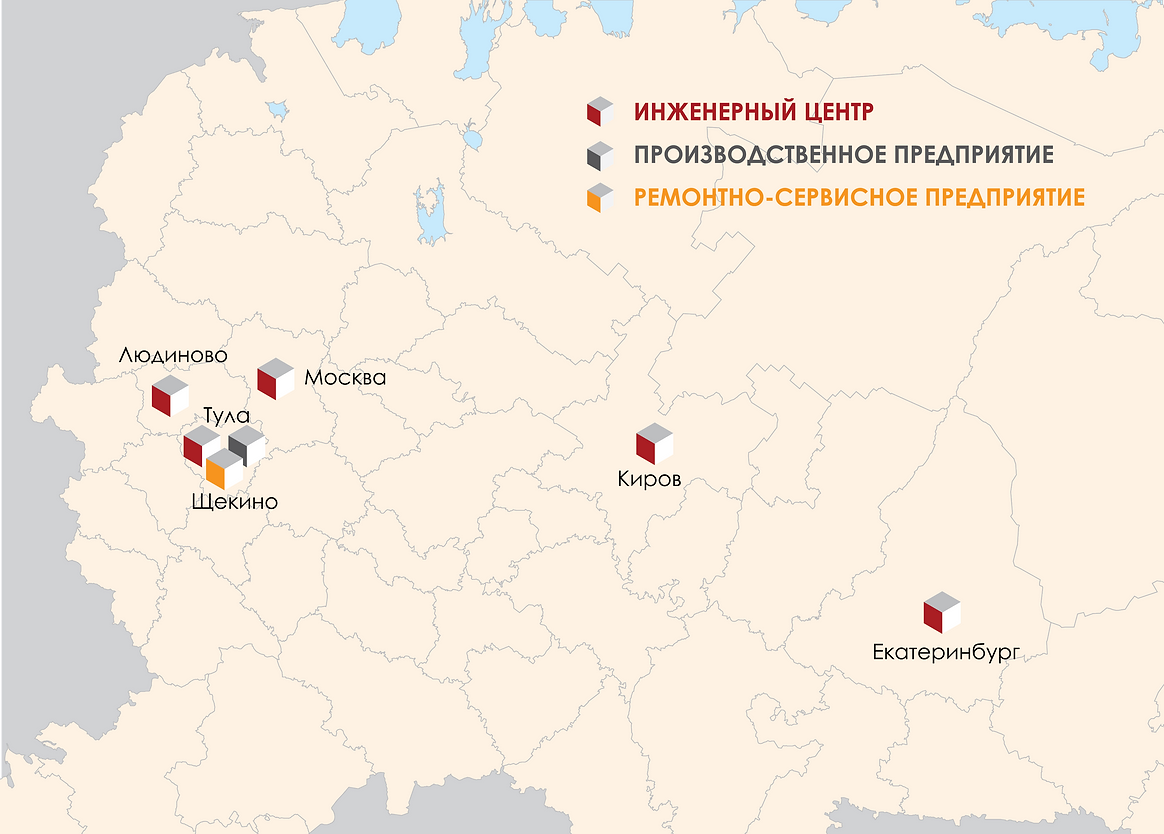

The PTK Group has created the largest in the industry Engineering Center specialising in the development of innovative track machines and technologies.

The PTK group has completely updated the line of machines that perform the whole complex of works on ballast section. According to its technical characteristics, the new products significantly exceed Russian and foreign analogues and allow to obtain a significant economic effect.

The Group includes one of the oldest Russian company in the field of railway engineering JSC "Tulazheldormash", which produces railway equipment since the second half of the 19th century. At present, JSCo "Russian Railways" operates over 2,000 units produced at the plant.

The PTK Group provides full service support, repair and operation of all produced machines

The business direction "Track machinery" is the priority of PTK Group development.

Taking into account the existing competencies, we develop and produce modern track machines,

and also provide the Customer with services based on the life-cycle contract principle

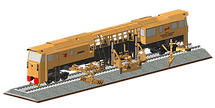

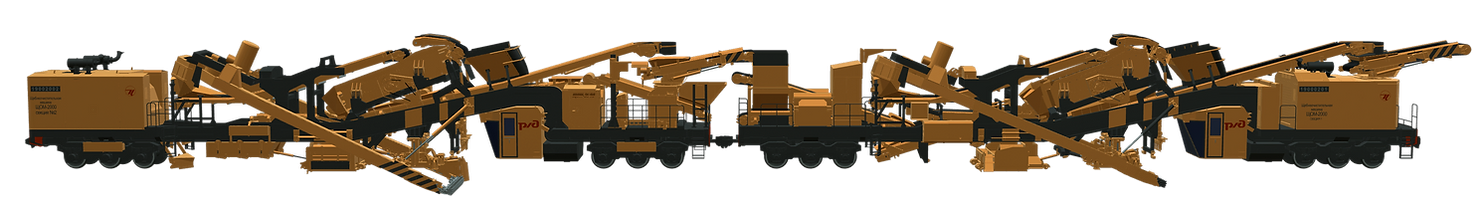

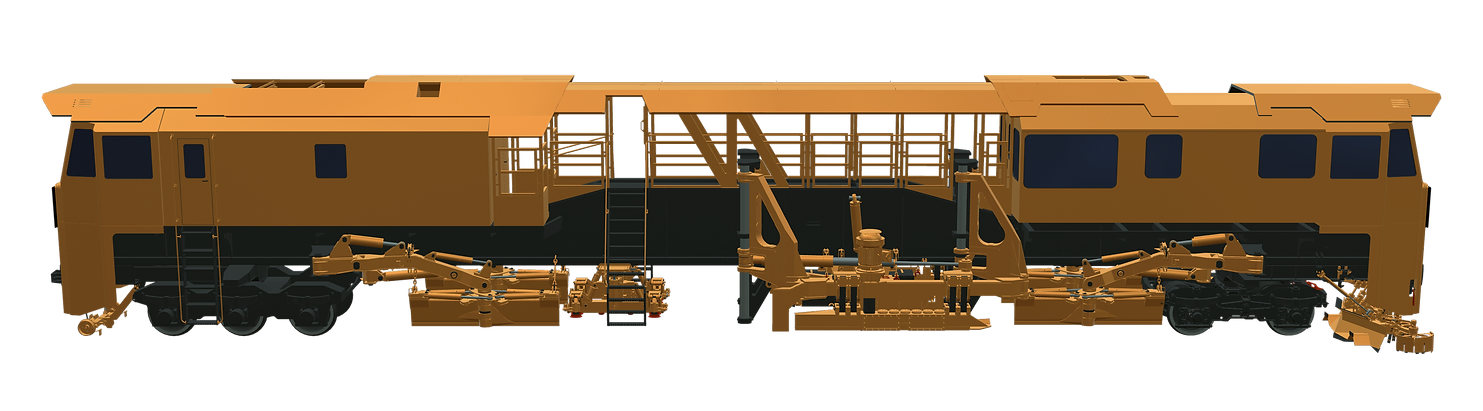

BCM-2000 – High-performance Ballast Cleaning Machine

Designed for mechanised cleaning of breakstone ballast from contamination

- Productivity, "cleaning" mode m³/h

- Productivity, "cut-out" mode m³/h

- Ballast cutting width, mm

- Ballast cutting depth from the sole of sleepers, mm

- Traveling speed, km/h

- Working speed, self-propelled, km/h

- Life cycle, years

2000

1600

3900-6000

200-1000

80

0,06-1,5

35

1600

3900-6000

200-1000

80

0,06-1,5

35

Основные характеристики

- Operating speed 750 m/h (2 times higher than analogues) is commensurate with the speed of operation of the whole complex of machines for repairing the track with traditional technology, which significantly reduces the overall repair time.

- Multipurpose – the ability to work with a single complex with maximum performance, and also each section separately for solving local problems.

- Multifunctionality – the ability to work in different technological chains (high-speed cleaning, complete cutting, complete cutting with separation, the creation of sub-ballast layers).

- Significant reduction in the cost of work.

Потребительские свойства

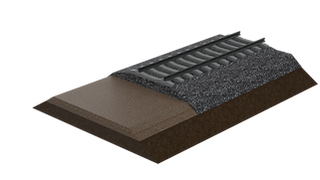

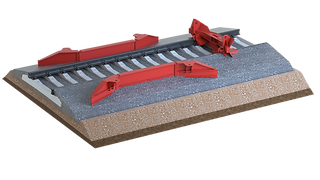

Stages of BCM-2000 machine operation

1

Old ballast layer

2

Cutting of old ballast layer

with two bar devices

with two bar devices

By performance BCM-2000 has no analogues in the world

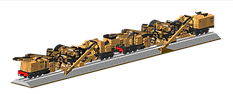

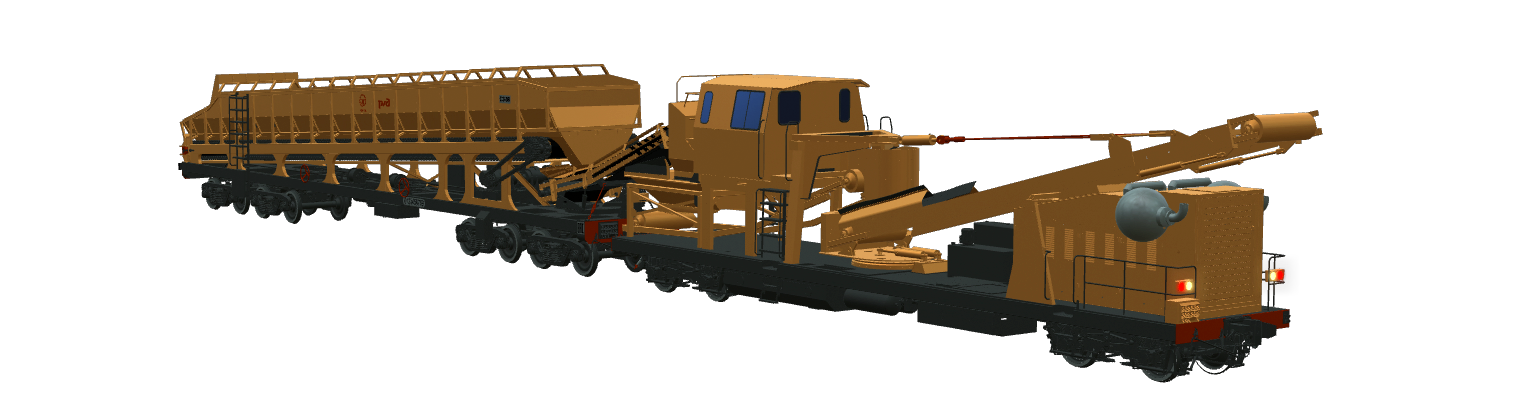

MML-88 – Machine for Material Logistics

Designed for loading, transporting and unloading of breakstone materials and contamination

- Load capacity, t

- Powerplant output, kW

- Power of conveyor motors, kW

- Time of unloading through the end car, min

- Distance of unloading from the track axis, when unloading through the end car, m

- Time for parallel unloading, min

- Capacity of carriage, m³

635

650

34 и 22

19,5

12

3,9

375

650

34 и 22

19,5

12

3,9

375

Main features

- High turnover speed of the train due to simultaneous unloading of all cars.

- Possibility of unloading over long distances through the end car.

- The possibility of embedding in technological chains (creating sub-ballast protective layers) to compensate different machine performance.

- Significant reduction in the cost of work.

Consumer properties

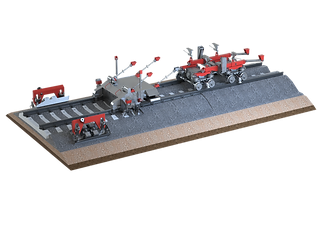

Stages of MML-88 machine operation

1

Accumulation and

removal of ballast to

the base for cleaning

removal of ballast to

the base for cleaning

2

Delivery of sand gravel mix from the base, sand-gravel mix feeding to the RFM-100

Machine for material logistics MML-88 participates both in the formation of a volumetric-compacted ballast section and protective sub-ballast layers, and in the high-speed ballast cleaning processes, performing the entire cycle of work on the turnover of inventories:

3

Delivery and feeding

of ballast to the

RFM-100

of ballast to the

RFM-100

By capacity and unloading speed, MML-88 has no analogues in the world

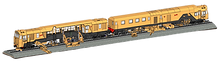

MPV – Primary Surfacing Machine

Designed for complex alignment and stabilisation of the track, performs the functions of ballasting, straightening, tamping and finishing surface

- Productivity, m/h

- Max. track raising, mm

- Max. track alignment, mm

- Crew, number of people

- Powerplant output, kW

- Life cycle, years

2000

250

350

5

1000

35

250

350

5

1000

35

Main features

- Work on raising and aligning the track with volumetric ballast compaction, stabilising the track and compacting the tie space. The work is carried out with the simultaneous setting of the way in the design position.

- Reducing operating costs by reducing the number of locomotives and the number of crews.

- Availability of an accomodation.

- Reduced repair time.

Consumer properties

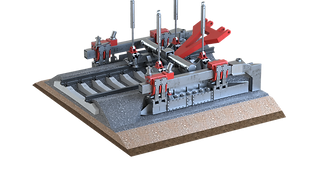

Stages of MPV machine operation

3

Redistribution of ballast into road bed and formation of ballast shoulder

4

Track alignment, sleeper surfaces

cleaning and ballast shoulder

compacting

cleaning and ballast shoulder

compacting

1

Formation of ballast in the working

area of vibrating tamper plate

area of vibrating tamper plate

2

Track alignment with volumetric

compacting of ballast

compacting of ballast

BCM-1200s – Ballast Cleaning Machine

Designed for cleaning ballast on the haul with a capacity of up to 1000 m³/h

- Productivity, "cleaning" mode m³/h

- Productivity, "cut-out" mode m³/h

- Ballast cutting width, mm

- Ballast cutting depth from the sole of sleepers, mm

- Traveling speed, km/h

- Working speed, self-propelled, km/h

1000

800

3900-5200

200-600

80

0,06-1,5

800

3900-5200

200-600

80

0,06-1,5

Main features

- Reducing operating costs by reducing the crew, excluding the separate traction unit from the complex, and reducing the energy intensity of the internal users of the machine.

- High working speed (up to 400 m/h) for ballast cleaning, providing an average daily pace of repair of the track up to 4 km/day.

Consumer properties

ЩОМ-1200С – высокопроизводительная машина с низкой стоимостью жизненного цикла

LFM-S – Track alignment, ballast section compacting and equalising machine

Designed to perform work with average and major repairs, as well as the construction of a railway track

- Max. tamping productivity, sleepers/h

- Working speed, self-propelled, km/h

- Number of lifting and straightening devices

- Lifting range, mm

- Shifting range, mm

3000

0-5

2

300

300

0-5

2

300

300

Main features

- The highest productivity for alignment and tamping of the track among machines of this class – more than 3000 sleepers/h.

- Reducing operating costs by eliminating a separate locomotive from the complex.

- Expanding the functionality of ballasting the track by increasing the height of the rail-sleeper grid by 300 mm.

- The application of the technology of volumetric compaction of the ballast

- section has been worked out, that makes it possible to increase its bearing capacity.

- Hydrostatic drive in operating mode ensures smooth running and uniformity of ballast compaction throughout the entire work front.

Consumer properties

LFM-S – has world analogues in terms of functionality and performance ratio

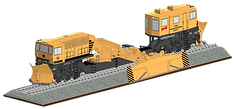

PDP – Powerful Dump Plough

Designed for earth and snow removal

- Productivity at cutting, levelling land and ballast, m³/h

- Productivity in clearing from snow, m³/h

- Max. height of snow, m

- Width of cleared way from snow, m

- Movement speed on earthwork, km/h

- Max. movement speed during snow clearing, km/h

- Max. wing outreach from the track axis, m

1200

15000

1

3,2

6-10

40

6

Main features

- Min up to 100 m radius of fitting in the curves of the railway track during transportation and in operation, which ensures wide application of the machine in any industrial enterprises.

- Increased life of operating devices before major repairs due to the use of wear-resisting steel on working surfaces.

- Wide temperature range of use (±50°С).

Consumer properties

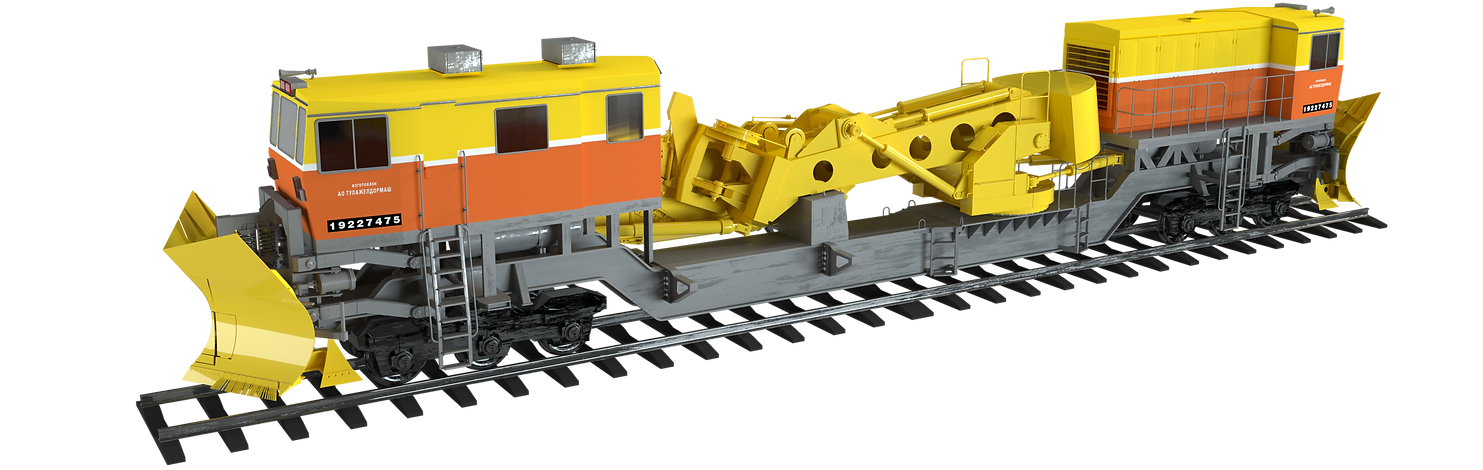

SBM – Snow Blowing Machine

Designed for excavation and snow-removal operations

- Productivity when cutting cuvettes, m³/h

- Productivity when cutting, levelling land and ballast, m³/h

- Productivity in clearing from snow, m³/h

- Max. height of snow, m

- Movement speed on earthwork, km/h

- Movement speed during snow clearing, km/h

- Max. wing outreach from the track axis, m

1050

3000

62500

1,5

3-15

до 20

7,8

3000

62500

1,5

3-15

до 20

7,8

Main features

- Reducing operating costs by eliminating a separate locomotive.

- Increased productivity on earthwork more than 2 times due to the use of a hydrostatic drive of the machine and the possibility of a reversible direction of work.

Consumer properties

TM-500 – Trencher Machine

Designed for cleaning and cutting cuvettes, forming the shoulders and slopes of the ballast section

- Productivity, m³/h, not less than

- Deepening of rotor device from the rail head top level, m, not less than

- Extension of the rotor device along the edge of the buckets relative to the axis of the track at work, m

- Working speed, self-propelled, km/h

400

2,8

1,4-8,4

0,1-4

2,8

1,4-8,4

0,1-4

Main features

- Reducing operating costs by reducing the crew, excluding the separate traction unit from the complex, and reducing the energy intensity of the internal users of the machine

- The highest productivity of the rotary device is not less than 400 m³/h in comparison with analogues.

- Service life of rotary device is doubled before major overhaul.

Consumer properties

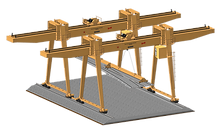

Equipment for track bases

- Lifting height from the level of the head of the crane rail to the bottom of the spreader, m

- Capacity under the console

- Working radius of consoles, m

- Span, m

- Temperature, °С

- Permissible wind speed at a height of 10 m above the ground, m/s:

in non-working condition not more

1050

3000

62500

1,5

3-15

до 20

7,8

Main features of cranes

The PTK Group designs and produces various types of equipment for track bases – track machines, complexes, and cranes in accordance with the requirements of the Customer, which allows the Group to install both fixed and temporary bases.

Electric gantry cranes are designed for reloading containers and piece cargo at railway stations, reloading terminals, warehouses and other industrial facilities.

More than 1500 cranes produced by PTK Groupare operated on the territory of the Russian Federation