EFFECTIVE

INNOVATIVE

CONTEMPORARY

PRODUCTION

TECHNOLOGIES

COMMUNICATIONS

EN

Innovative technologies of track repair

Effective technologies are the vector of PTK Group development

JSCo "Russian Railways" set a task to modernise the transport infrastructure and introduce modern technologies to increase efficiency and optimise costs.

Scientific and Technical Council of JSCo "Russian Railways", including for the development of highspeed and heavy traffic, defined the requirements for advanced technologies for repairing the track, as well as for high-performance track machine complexes.

Based on these requirements, the PTK Group together with JSCo "Russian Railways" developed new technologies and technical requirements for track machine complexes, as well as feasibility studies that prove the economic effect of their implementation.

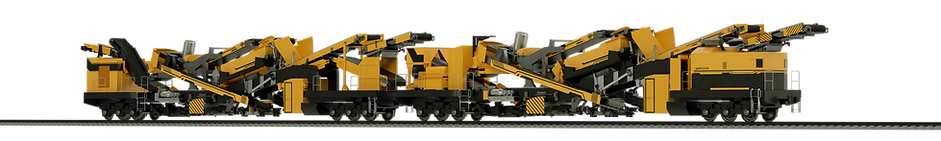

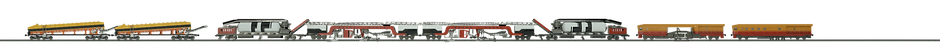

On the basis of a new line of machines, a multipurpose track complex for a ballast section has been created. The modular design has unique technical features, allows the use of high-performance machines in various track repair technologies. Our technical solutions have no analogues, that is confirmed by patents.

Multipurpose track complex for ballast section

BCM-2000

MML-88

RFM-100

The economic effect of the introduction of new technologies for repairing the track on the basisof a multipurpose complex is at least 34%

High-speed ballast cleaning technology

The result of technology implementation

Ballast contamination is the main cause of track defects and ballast section cleaning is the main source of costs for maintenance of the railway infrastructure.

Low productivity of ballast cleaning machines is a deterrent in improving the efficiency of track repair.

Low productivity of ballast cleaning machines is a deterrent in improving the efficiency of track repair.

- increase the speed of the ballast cleaning machine during the track repair to up to 750 m/h;

- increase the capacity and turnover of machines for material logistics with the optimisation of the logistics scheme;

- increase the efficiency of the entire technological process of repairing the track.

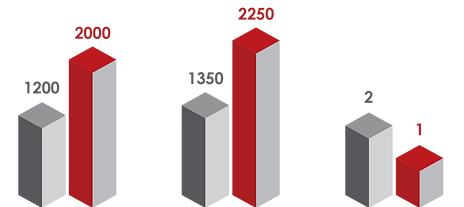

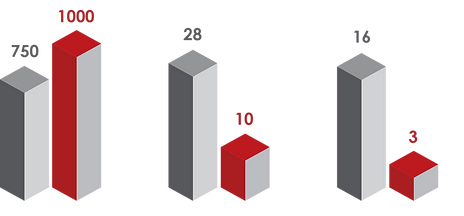

Technical and economic indicators

MML-88

BCM-2000

Machine for material logistics

Ballast cleaning complex

Current technology

Applicable machines:

BCM-1200,

MML-800

BCM-1200,

MML-800

New technology

Applicable machines:

BCM-2000,

MML-88

BCM-2000,

MML-88

Technical productivity, m³/h

Output in an 8-hour “window”, m/track

Number of locomotives and UTM involved

The introduction of the High-speed ballast cleaning technology based on BCM-2000 machine provides an increase in output by 2.5 times

For example, on the length of the site at 1000 meters the time of work on the new technology is reduced to 260 minutes compared to 478 according to the existing technology

Protective sub-ballast layers formation technology

The result of technology implementation

For the high-speed and heavy traffic organisation, a compacted layer-by-layer protective sub-ballast layer, which enhances the bearing ratio of the roadbed and prevents the contamination of the ballast section, is of particular importance.

- significant increase in the speed of work (up to 100–150 m/h);

- optimisation of the logistics scheme due to the organisation of local areas for material storage and preparation;

- significant reduction in material costs due to the efficient use of secondary materials.

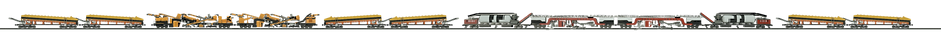

Technical and economic indicators

MML-88

BCM-2000

Machine for material logistics

Ballast cleaning complex

Current technology

Applicable machines:

BCM-1200, MML-800, UK-25/9-18,

MPD, USO, HD, PB, ELB, ROM,

Autograders, Vibrorollers

BCM-1200, MML-800, UK-25/9-18,

MPD, USO, HD, PB, ELB, ROM,

Autograders, Vibrorollers

New technology

Applicable machines:

BCM-2000, MML-88,

RFM-100

BCM-2000, MML-88,

RFM-100

Output in an 8-hour “window”, m/track

Number of machines involved

Number of locomotives or UTM involved

The introduction of Protective sub-ballast layers formation technology provides an increase in production by 2.5 times in comparison with forein analogues

For example, on a length of 4500 meters, the time of work on the new technology was reduced to 4821 minutes compared to 8709 minutes according to the existing technology

MML-88

RFM-100

MML-88

Machine for material logistics

Sand and gravel volumetric compaction complex

Machine for material logistics

Volumetric-compacted ballast section formation technology

The result of technology implementation

The traditional technology of ballast section formation provides for the need to limit the speed of train traffic with the subsequent increase in speed as additional work is carried out (additional ballasting, straightening and stabilising the track).

- increase the train speed up to 80 km/h immediately after the repair;

- reduction in the number of stages of work by eliminating the need of additional ballasting of the ballast section;

- reduction of costs for current track maintenance, minimisation of local track defects.

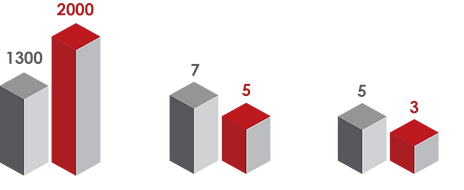

Технико-экономические показатели

MML-88

RFM-100

Machine for material logistics

Sand and gravel volumetric compaction complex

Current technology

Applicable machines:

HD, ELB, VPR, DSP,

LFM-3000, PB

HD, ELB, VPR, DSP,

LFM-3000, PB

New technology

Applicable machines:

MML-88, RFM-100,

MPV

MML-88, RFM-100,

MPV

Output in an 12-hour “window”, m/track

Number of machines involved

Number of locomotives or UTM involved

The introduction of the Volumetric-compacted ballast section formation technology

will provide a significant reduction in the cost of work, as well as reducing the time for repairing the track and increasing the speed of traffic

will provide a significant reduction in the cost of work, as well as reducing the time for repairing the track and increasing the speed of traffic

For example, on the length of 1000 meters the time of work on the new technology was reduced to 697 minutes compared to 1093 minutes according to the existing technology.

MPV

Primary surfacing

machine

machine

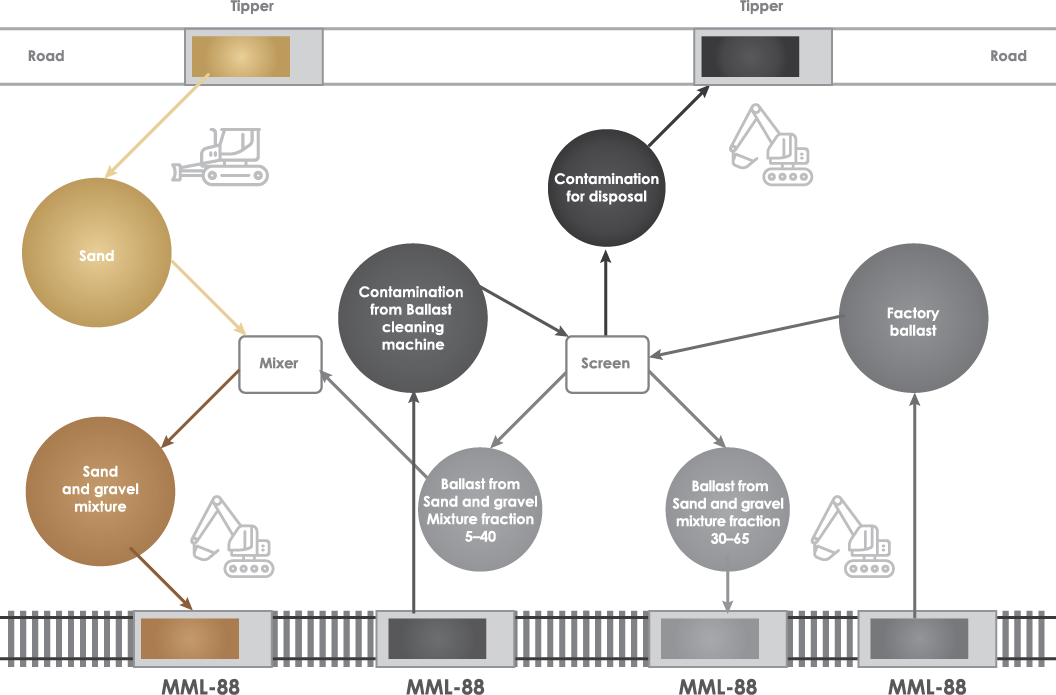

Local storage areas organisation

Tasks

The main reason for high costs and a long period of track work is the remoteness of places for loading ballast materials.

- organisation of temporary local bases within 30 km from the site of work;

- delivery of materials with the help of new quickly loaded carriages for the material logistics MML-88

The scheme of local bases organisation

With considering the existing competencies, we create effective solutions for the logistics organisation in new technologies for repairing the track.

The result of technology implementation

- сontinuity of work of complexes, optimisation of logistics;

- efficient use of secondary materials.